2023 LTL Study: Partner for reliability

While rates continue to rise, shippers who’ve worked to form closer partnerships with their LTL providers report better pricing, better service and improved support from their carriers.

With U.S. e-commerce sales crossing the $1 trillion mark for the first time in 2022, demand for LTL shipping has been rising steadily over the last few years. With each shipper’s merchandise only taking up a portion of the vehicle’s space, companies only pay for what they actually use.

And while it costs more to contract a full truckload, LTL rates are usually higher—and appear to be holding their own this year, despite a leveling off of freight rates overall—due to convenience and other factors.

To gain a better understanding of the current LTL environment and the companies that use this vital mode of freight transportation, Logistics Management recently conducted its “2nd Annual LTL Study” with the help of Peerless Research Group (PRG). Data for the study was based on feedback from more than 215 buyers of logistics and freight transportation services. Here’s what we learned.

Rates continue to increase

Freight rates may have leveled off for some shippers in 2023, but for the most part, LTL users continue to see their transportation prices escalate.

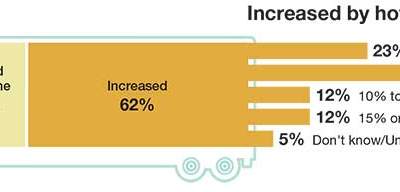

From 2022 to 2023, most respondents (62%) say that their LTL contract rates have increased, while 25% say rates have stayed the same and while 13% of respondents say they’ve seen their LTL rates decrease during that period.

Of the companies that have seen their LTL rates increase, 49% say that increase was between 5% and 9%, while 23% say it was less than 5%, and 12% say it was between 10% and 14%. Another 12% say rates increased by 15% or more.

Companies reporting LTL contract rate decreases say those drops were less than 5% (for 31% of respondents), 10% to 14% (31%) or 5% to 9% (19%). Another 15% say that their LTL contract rates decreased by 15% or more.

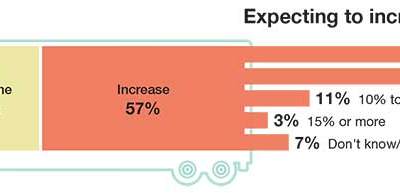

Looking out over the next 12 months, 57% of those surveyed expect LTL contract rates to increase again, while 32% expect them to stay the same and 11% expect a decrease. Forty-two percent of those expecting an increase in 2024 are bracing for a jump of 5% to 9%; 38% expect the decrease to be less than 5%; while 11% expect a decrease of 10% to 14%.

Asked why they think LTL rates are on track to increase over the next 12 months or so, respondents point to capacity, labor costs, overall rising costs, driver shortages, fuel prices and supply chain disruptions/delays as some of the key drivers.

According to the survey, 44% of respondents who are anticipating LTL rate decreases over the next 12 months are expecting a break of 5% or less; 35% expect a 5% to 9% decrease; and 17% are anticipating a 10% to 14% decrease.

Securing capacity

Twenty-eight percent of this year’s survey respondents ship between 1,000 and 9,999 domestic and international shipments annually. An equal percentage are sending out less than 1,000 shipments while 20% fall into the 10,000-49,999 range. Twelve percent of participants work for organizations that ship 200,000 or more shipments annually.

In order to keep up with e-commerce deliveries, 34% of companies are using more LTL, while 66% haven’t had to secure more LTL capacity in response to the uptick in online sales. Overall, 40% of respondents say e-commerce has not made an impact on their business, while 43% say it has “somewhat affected” them, and 17% say they’ve been “highly affected” by the current e-commerce trends.

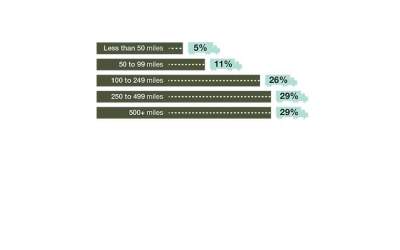

In terms of average length of haul, 29% of logistics professionals say that it’s more than 500 miles; 29% say 250 miles to 499 miles; and 26% say 100 miles to 249 miles. Eleven percent of respondents are shipping 50 miles to 99 miles and 5% are shipping goods to an area within 50 miles of their distribution hubs.

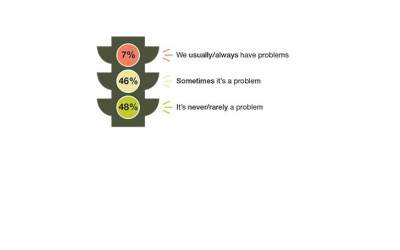

About half (48%) of respondents say securing LTL capacity is “never” or “rarely” an issue for them, while 46% say it’s “sometimes” a problem and 7% “nearly always” have an issue getting the LTL capacity that they need.

Asked to share what specific issues they encounter when securing LTL capacity, respondents point to a lack of availability, capacity, delivery delays, driver shortages, finding good drivers or shippers, scheduling and unpredictability as their biggest pain points.

To offset these issues and secure the LTL capacity that they need to cover their loads, respondents are seeking out alternative suppliers or modes, more thoroughly evaluating suppliers, building long-term relationships with their carriers, and consolidating orders. Others are using more demand planning and working with third-party logistics (3PL) providers or freight brokers.

When asked what they’re doing to better manage their overall LTL freight operations, shippers say that they’re automating processes, enforcing better planning habits, improving their communication, consolidating shipments, diversifying their networks and/or implementing new transportation management systems (TMS).

Forming strong partnerships

Of the companies surveyed, 36% secure LTL loads and capacity via the spot market while 64% do not use this strategy.

Twenty-nine percent of respondents that do use the spot market say that their current contract is one week to less than two weeks long, while 27% say their contract covers less than one week. Twenty-one percent have spot contracts that extend one month or longer and 10% say their contracts range from two weeks to four weeks in length.

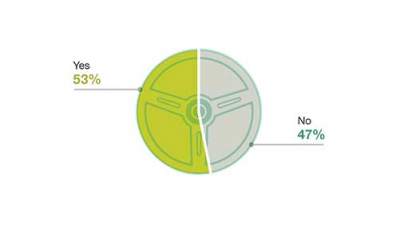

Just more than half (53%) of respondents have taken steps to form closer partnerships with their LTL carriers, while 47% haven’t used this strategy. Those that have worked to form closer partnerships with their LTL providers report better pricing, higher reliability, better service and improved support from their carriers. Others say that these tighter bonds have resulted in better responsiveness on the carriers’ part, more accurate pickups, increased capacity and better operational alignment.

Roughly half (55%) of the LTL providers that survey respondents are working with are national in scope, and 45% focus on specific geographical regions. When asked what they’re looking for in an LTL partner, respondents say that accuracy, better rates, collaboration, consistency and dependability are top of mind. Other companies are looking for flexibility, better customer service, less damages and more visibility from their LTL carriers.

Who’s using LTL?

Nearly half (42%) of this year’s survey respondents are involved in the authorization or approval of transportation, trade, warehousing, inventory or other logistics related functions for either their organization or others. Sixteen percent of participants are involved in the selection of brand or suppliers, 15% suggest or determine need, 14% recommend suppliers and 13% evaluate suppliers.

This year’s survey respondents hold a variety of roles, including VP/general manager (19%); logistics or distribution manager (15%); corporate or divisional manager (11%); purchasing or procurement manager (13%); and operations manager (10%). They also represent a wide range of companies, including manufacturers (44%), wholesalers (17%), transportation/warehousing services (12%) and 3PLs (10%).

As for company size, 39% of respondents work for firms with less than 100 employees; 24% say their company size is 100 employees to 499 employees; 11% say 500 employees to 999 employees; and another 11% say they work for firms with 1,000 employees to 4,999 employees. Fifteen percent of survey participants work for organizations with 5,000 or more associates.

Looking ahead

When asked where they see the LTL market one year from now, many survey respondents say they expect it to stay the same, with others expecting higher prices or tighter capacity. Still others are hopeful that the LTL environment will improve—only a few believe it will get worse than it is now.

Three years from now, some respondents expect the LTL market to be “back to normal” or at pre-pandemic levels. Others are unsure about what’s ahead or expect the environment to stay the same as it is now. Looking out five years, respondents are more unsure of exactly what the LTL market will look like, but many are hopeful that it will improve or stay the same.

Article Topics

LTL News & Resources

Q&A: Ali Faghri, Chief Strategy Officer, XPO Mastio’s Huntsman provides overview of LTL shipper and carrier relationship dynamics Knight-Swift solidifies national LTL presence with AAA Cooper integration of MME and DHE Cass Freight Index shows signs of recovery in September Q3 TD Cowen/AFS Freight Index highlights how carriers fight margin pressure amid lengthy downcycle Truckload, parcel, and LTL executives address regulatory uncertainty, market fragmentation at CSCMP EDGE Echo Global Logistics makes further inroads in Mexico, with the opening of new Monterrey location More LTLLatest in Logistics

Q3 intermodal volumes see annual gains, reports IANA Manufacturing declines for the ninth consecutive month, reports ISM Looking at the impact of tariffs on U.S. manufacturing UP CEO Vena cites benefits of proposed $85 billion Norfolk Southern merger Proposed Union Pacific-Norfolk Southern merger draws praise, skepticism ahead of STB Filing National diesel average is up for the fourth consecutive week, reports Energy Information Administration Domestic intermodal holds key to future growth as trade uncertainty and long-term declines persist, says intermodal expert Larry Gross More LogisticsAbout the Author

Subscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

November 2025 Logistics Management

Latest Resources