Benchmarks with Becky Partida: Sales order automation benefits the supply chain

Automating order processing can shorten cycle times and reduce errors that affect the supply chain.

Efficient order fulfillment is a key factor in maintaining strong relationships with customers, whether or not they are strategic partners. Yet many organizations struggle with getting this right, as they rely heavily on manual processes with significant data entry. Manually processing orders can lead to significant disruptions caused by order input errors, a lack of integration between the order database and other internal systems, and a lack of visibility into the end-to-end process of creating, filling and delivering orders.

Sales order automation offers the potential for eliminating many of these errors and interruptions. This in turn can provide quantifiable benefits to the organization. When adopting sales order automation, APQC recommends automation specifically for processing sales orders, not solely adopting an electronic data interchange (EDI) for sales orders or an enterprise resource planning (ERP) system for inventory control. Both internally developed systems and those purchased from an external vendor offer benefits over organizations relying on manual processes.

APQC recently conducted research on this topic in partnership with Esker, a document processing automation solution provider. The goal of the research was to identify how different sales order automation practices affect performance on key measures. For the supply chain, automating sales order processing can lead to benefits with regard to order cycle time and perfect order performance.

Evaluating first-time data accuracy

Organizations changing from manual order processing and fulfillment to an automated process will see improved accuracy. However, an organization wanting to evaluate its automated process can track first-time data accuracy for quotes and order management. An effective order fulfillment system typically provides standard forms, drop-down menus and preset order numbers to minimize input errors and thus increase first-time data accuracy. APQC has found that organizations that measure, track and reward first-time data accuracy are 2.8 times more likely to find their order management extremely effective at improving order fill rates and on-time delivery compared with organizations that do not.

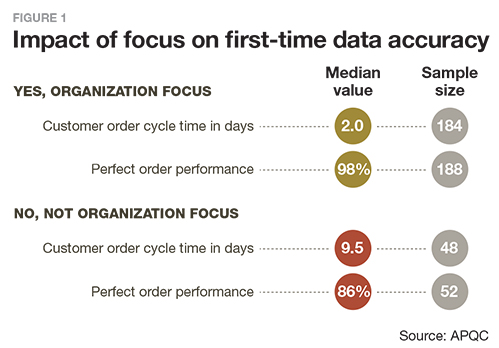

As shown in Figure 1, those organizations measuring first-time data accuracy have much shorter customer order cycle times, or the time between order placement and delivery. At the median, their cycle time is about one week shorter than that of organizations not focusing on first-time data accuracy—indicating a significant impact from eliminating manual processing time and errors.

As shown in Figure 1, those organizations measuring first-time data accuracy have much shorter customer order cycle times, or the time between order placement and delivery. At the median, their cycle time is about one week shorter than that of organizations not focusing on first-time data accuracy—indicating a significant impact from eliminating manual processing time and errors.

These organizations also have higher perfect order performance than their counterparts that do not focus on first-time data accuracy. At the median, organizations that focus on first-time data accuracy achieve a perfect order performance of nearly 100%, meaning that nearly all of their orders arrive to customers complete, on time, damage free and with correct documentation. By contrast, organizations that do not focus on first-time data accuracy have a perfect order performance of only 86%. Although this number is still high, the potential impact of orders that are not perfect should make organizations strive to achieve as high a perfect order performance as possible.

APQC’s data indicates that sales order automation and a focus on data accuracy can spur organizations to make significant strides in performance. Measuring and rewarding accurate data can motivate employees within the organization to embrace automation and highlight automation’s benefits across functions responsible for processing and shipping customer orders.

These results are not limited to the organizations in APQC’s data. In its work with organizations, Esker found that the medical device organization MEDRAD Inc. decreased its order entry errors from 1.6% to less than 0.4% by focusing on first-time data accuracy. Furniture manufacturer Kimball International achieved and maintained an order entry accuracy rate of 99.6% after adopting a focus on first-time data accuracy.

Reducing human intervention

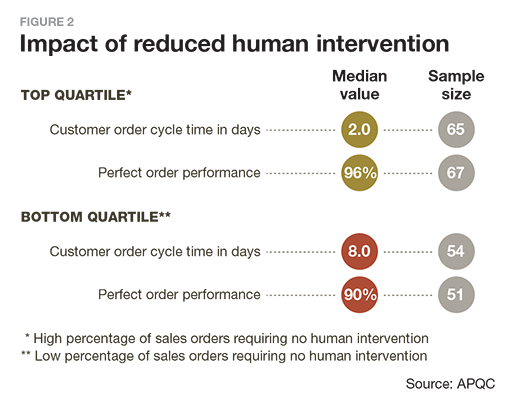

Ultimately, the goal of automating sales order processing is to reduce the amount of human intervention needed in the process. APQC’s analysis found that organizations with a lower degree of human intervention perform better than their counterparts requiring more human intervention. For its analysis, APQC identified the group of organizations in the top quartile (meaning they have a high percentage of sales orders requiring no human intervention) and the group of organizations in the bottom quartile (meaning they have a low percentage of sales orders requiring no human intervention).

As shown in Figure 2, organizations in the top quartile perform better with regard to customer order cycle time and perfect order performance. At the median, organizations in the top quartile have a median customer order cycle time of two days, whereas those in the bottom quartile have a cycle time of eight days. The nearly one-week difference between the two groups is a strong indicator that, to realize the full benefits of automation, organizations should make an effort to limit the amount of human intervention needed to process sales orders.

As shown in Figure 2, organizations in the top quartile perform better with regard to customer order cycle time and perfect order performance. At the median, organizations in the top quartile have a median customer order cycle time of two days, whereas those in the bottom quartile have a cycle time of eight days. The nearly one-week difference between the two groups is a strong indicator that, to realize the full benefits of automation, organizations should make an effort to limit the amount of human intervention needed to process sales orders.

Organizations in the top quartile also have a greater perfect order performance rate than their counterparts in the bottom quartile. At the median, those in the top quartile have a six percent higher performance rate than those in the bottom quartile. At 90%, the perfect order performance of bottom quartile organizations is not disappointing, but to maintain positive relationships with customers and an advantage over competitors, organizations would be wise to take measures that could improve their perfect order performance.

APQC’s data clearly shows the advantages of sales order automation. Esker has found that these results hold true with organizations across industries. For example, the pharmaceutical company Accord Healthcare automated its order processing to a moderate degree, with just under 65% of orders having no manual intervention. Even with this degree of automation, the organization was able to reduce its order processing time. Food distributor SanLucar automated its largely manual order fulfillment process and experienced 84% faster order processing times. Shorter order processing times themselves are a benefit to these organizations, but they also create benefits through the supply chain, resulting in greater percentages of on-time deliveries.

Selecting a sales order automation system

Automating order processing can reduce headaches for functions from production to logistics. Not only does a reduction or elimination of manual processing reduce errors in data entry, it also enables organizations to fill orders faster and thus make more of their deliveries on time. The practice also reduces the amount of returns caused by errors in order fulfillment.

In fact, APQC has found that organizations using order processing automation experience an average of 80% faster order processing speeds, as well as a decrease in order delivery times by several days.

Organizations should note that when implementing automation, they have a choice between using an internally developed system or an externally developed system they can purchase. Both enable benefits over manually processing orders, but there are performance differences between the two types of systems. Organizations using externally developed systems tend to have shorter customer order cycle times than their counterparts with internally developed systems. However, 75% of organizations with a commercial system find their order management extremely effective, whereas only 59% of organizations using an internally developed system feel the same way.

In determining the type of system to use, organizations should, of course, consider whether they have the resources needed to develop an internal system, or if it makes more sense from a financial and resource standpoint to adopt a system created externally. A system customized to the organization may be impressive, but it is not always necessary. They should also consider the complexity of their order intake process and the number of channels an order enters through. Organizations with a complex intake process and numerous intake channels may be best served by an externally-developed system. •

About APQC

APQC helps organizations work smarter, faster, and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org, and learn how you can make best practices your practices.

“Measuring and rewarding accurate data can motivate employees within the organization to embrace automation and highlight automation’s benefits across functions responsible for processing and shipping customer orders.”

Article Topics

Warehouse News & Resources

Looking at the impact of tariffs on U.S. manufacturing C.H. Robinson expands El Paso operations with 450,000 square-foot facility to meet rising Mexico trade demand Despite billions invested, supply chain technology is still falling short, says DHL report Logistics growth holds steady in October, states new edition of LMI Logistics real estate demand hits an inflection point, reports Prologis Industrial Business Indicator GXO posts record-setting Q3 earnings results Amid economic uncertainty, NRF forecast calls for a record retail holiday sales season More WarehouseLatest in Logistics

Looking at the impact of tariffs on U.S. manufacturing UP CEO Vena cites benefits of proposed $85 billion Norfolk Southern merger Proposed Union Pacific-Norfolk Southern merger draws praise, skepticism ahead of STB Filing National diesel average is up for the fourth consecutive week, reports Energy Information Administration Domestic intermodal holds key to future growth as trade uncertainty and long-term declines persist, says intermodal expert Larry Gross Railroads urged to refocus on growth, reliability, and responsiveness to win back market share Q&A: Ali Faghri, Chief Strategy Officer, XPO More LogisticsSubscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

November 2025 Logistics Management

Latest Resources